-

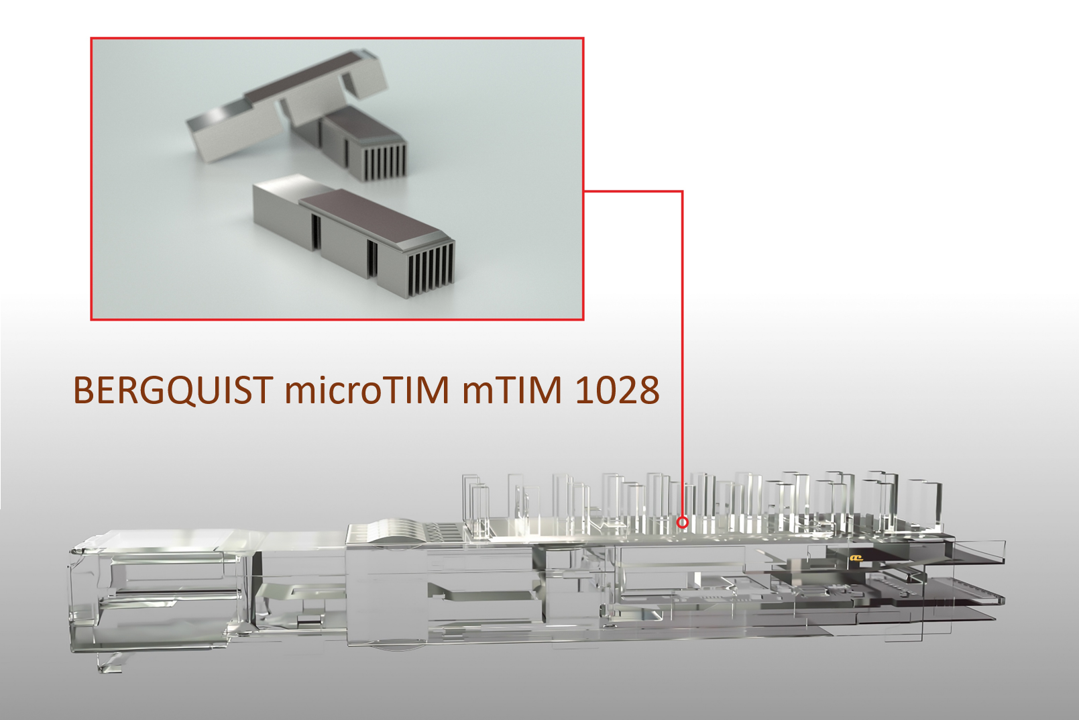

Item Name: LOCTITE® 403™

-

Manufacturer: Henkel

-

Technologies: Alkoxyethyl cyanoacrylate (low odor, low blooming)

-

Color: Transparent, colorless to pale yellow liquid

-

Cure Type: Humidity cure

-

Package Size: Contact to Techniq VN for details.

-

Shelf Life: Contact to Techniq VN for details.

Welcome to TECHNIQ VIETNAM