How can next-generation thermal interface materials revolutionize the reliability of advanced electronic assemblies?

✨ Market Trends: With electrification, miniaturization, and higher power density shaping automotive, industrial, and consumer electronics, the demand for efficient thermal management materials is accelerating. Electrostatics, dielectric performance, and heat conduction are now decisive factors in safeguarding the integrity of control modules, power units, and precision electronics.

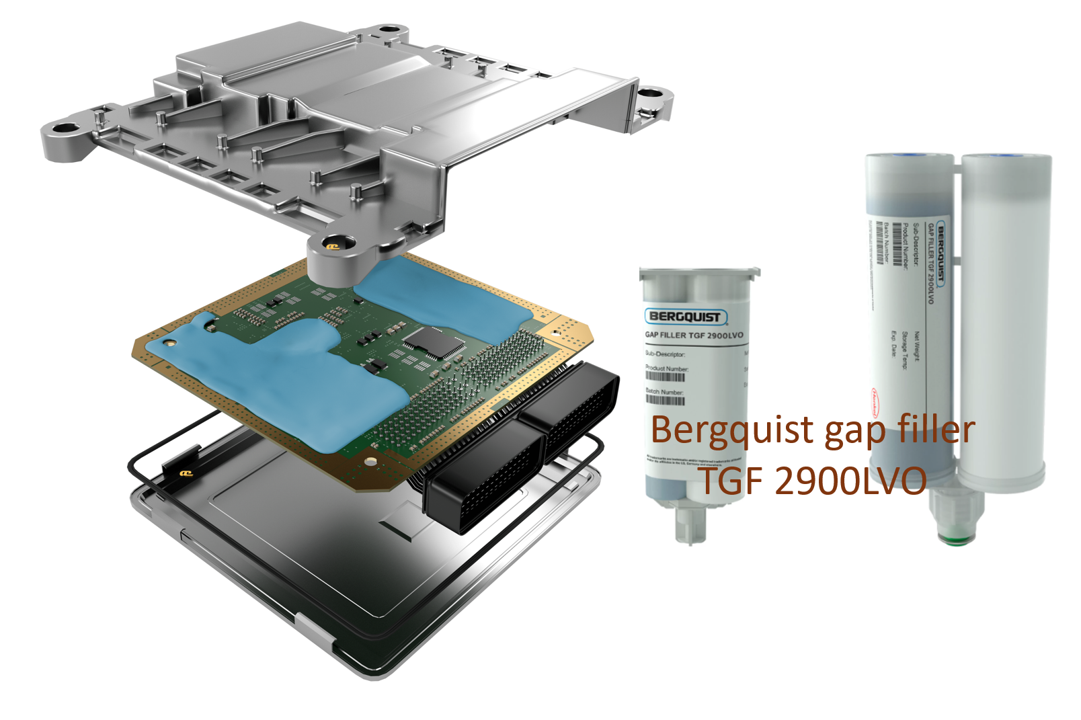

✨ Applications: BERGQUIST® GAP FILLER TGF 2900LVO, a silicone-based 2-component system, delivers optimized heat transfer across ultra-thin bondline interfaces. It is engineered for automotive control modules, high-throughput manufacturing lines, and electronics sensitive to siloxane outgassing, ensuring stable operation in environments spanning -40 °C to +150 °C.

✨ Highlights: With a thermal conductivity of 2.9 W/(m·K), dielectric constant of 6.78, and volume resistivity of 1×10¹⁰ Ω·m, this material unites chemistry and physics for outstanding performance. Its slump resistance, low abrasiveness, and low volatile outgassing further reinforce suitability for high-precision electronics and powder coating workflows where contamination control is critical.

✨ Product Advantage: Offering room-temperature cure, long working time, and stable dispensing with high shot consistency, TGF 2900LVO reduces thermal resistivity, enhances electro-thermal reliability, and simplifies processing. By combining high dielectric strength with controlled viscosity and superior gap-filling capacity, it establishes a benchmark for advanced electronic assembly and energy-efficient design.