How does Bergquist Hi Flow THF 5000UT redefine thermal interface technology for next-generation high-performance electronics?

✨ Market Trends: The acceleration of AI, high-performance computing, and ultra-dense industrial electronics demands thermal interface materials that deliver low impedance and high conductivity without imposing mechanical stress on delicate, thin-die architectures. Global competition emphasizes innovations that merge thermal physics, electrostatics, and materials science to secure both energy efficiency and device reliability.

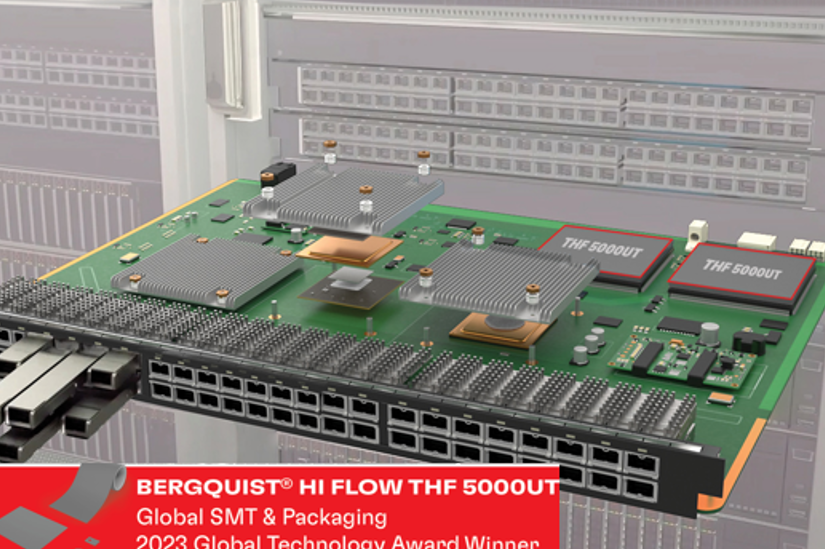

✨ Applications: Bergquist Hi Flow THF 5000UT is engineered for multi-die packages, networking processors, and advanced industrial assemblies where power density exceeds hundreds of watts. By forming an ultra-thin bond line under ultra-low pressure, it enables efficient heat dissipation while preserving structural integrity, ideal for HPC servers, telecom systems, and compact AI accelerators.

✨ Highlights: The silicone-free phase change formulation achieves thermal conductivity up to 8.5 W/m·K, with low thermal impedance values of 0.04 °C·cm²/W at 35 psi and 0.06 °C·cm²/W at <10 psi. Stable performance has been verified at operating temperatures up to 150 °C and across 800 W power ranges, ensuring robust reliability in extreme electrothermal environments. Its film-based medium eliminates mess, simplifies handling, and supports pre-application on heat sinks for streamlined production.

✨ Product Advantage: Bergquist Hi Flow THF 5000UT combines ultra-low stress, high thermal conductivity, and simplified processability, reducing both operational risk and manufacturing cost. With no pre-burn required, it accelerates assembly cycles while enhancing thermal protection of delicate semiconductor devices. Recognized with the Global Technology Award, this innovation demonstrates Henkel’s leadership in advancing thermal interface solutions for the most demanding electronic applications.