How does a next generation thermal interface material transform high power electronics by combining conductivity, electrostatic insulation, and production efficiency?

✨ Market Trends: The convergence of 5G infrastructure, e mobility, high density data centers, and industrial automation is pushing thermal loads beyond conventional dissipation limits. Market demand emphasizes ultra high thermal conductivity, low assembly stress, and scalable dispensing technologies aligned with sustainability.

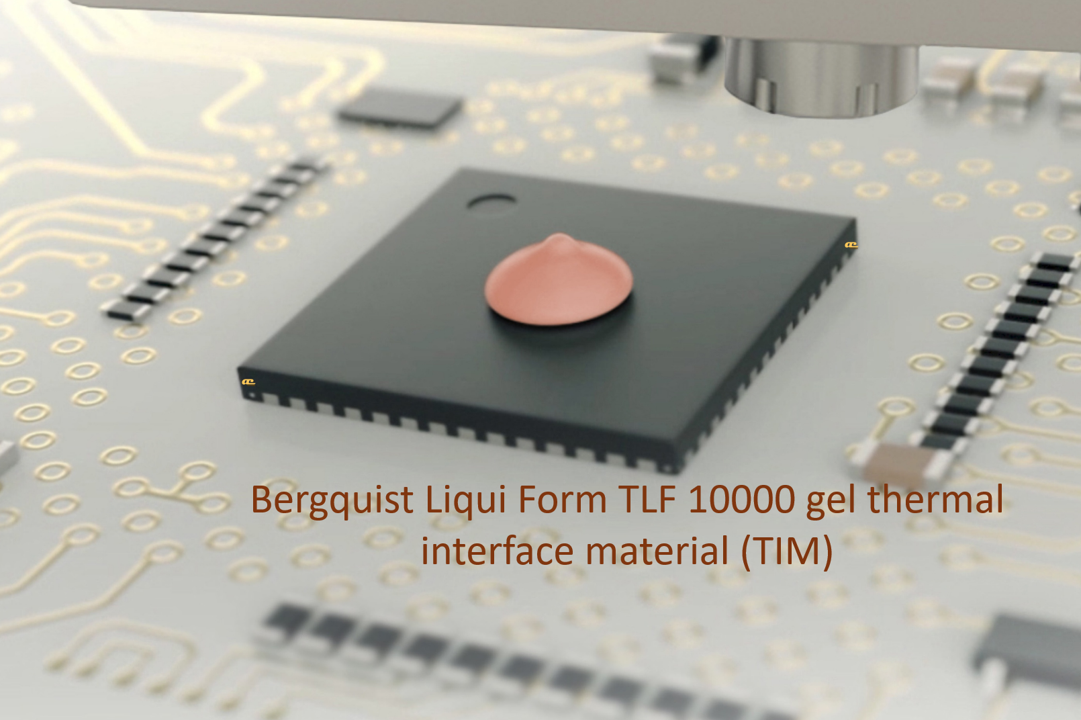

✨ Applications: BERGQUIST® LIQUI FORM TLF 10000 addresses critical hotspots in RRU/AAU/BBU units, EV battery packs, 5G antenna modules, industrial controllers, and compact PCBs while stabilizing vertical gaps ≤2.5 mm and preserving electrostatic reliability.

✨ Highlights: With thermal conductivity of 10 W/mK, dielectric strength of 7,084 V/mm, and flame retardancy UL 94 V0, this pre cured silicone gel ensures low thermal impedance, excellent cycling endurance, and minimal resin bleed, enabling precise dispensing even under high volume automated assembly.

✨ Product Advantage: Ready to use with no mixing or refrigeration, the gel offers stable viscosity, high gap retention, chemical robustness, and reworkability. This balance of physics driven thermal transfer, electrostatic shielding, and low mechanical stress establishes it as a superior TIM solution for next generation electronics.