How can micro thermal interface coatings engineered with silicone thermoset chemistry redefine heat dissipation efficiency and reliability in next generation optical transceivers?

✨ Market Trends: With hyperscale data centers migrating to 400, 600, and 800 Gb pluggable optical modules, thermal densities are intensifying. Traditional metal to metal interfaces and adhesive phase change materials are reaching physical and electrothermal limits, requiring advanced coatings capable of sustaining high thermal flux without degradation.

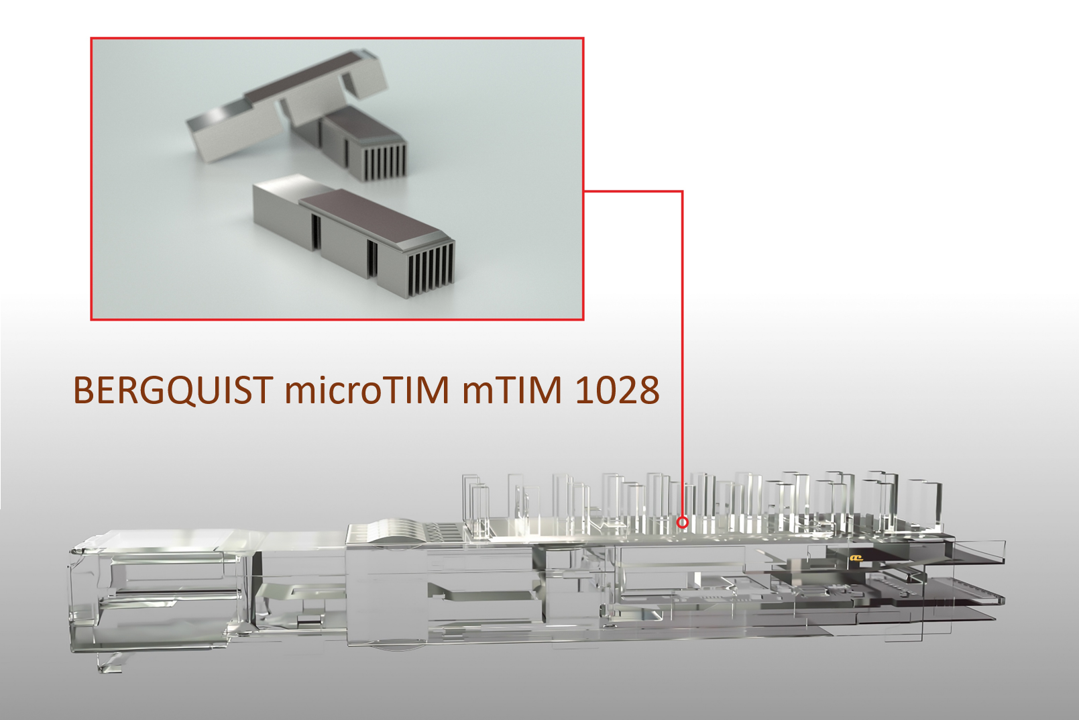

✨ Applications: BERGQUIST microTIM mTIM 1028 is purpose built for riding cage assemblies in servers, switches, and routers, interfacing with electroless nickel plated copper or aluminum heat sinks. It ensures stable operation in high power transceiver modules while also extending applicability to liquid cooling components, heat pipes, and fin based dissipative structures.

✨ Highlights: This tan colored silicone thermoset coating maintains constant thermal impedance even after 500 plug pull cycles, delivers a thermal resistance improvement of up to 0.18 °C/W, and withstands 300 °C thermal spikes without functional loss. Its elastomeric properties reduce abrasive wear, while its electrical volume resistivity (>1 GΩ·m) safeguards against parasitic leakage in high frequency data transmission environments.

✨ Product Advantage: Unlike conventional interfaces constrained by mechanical pressure and phase instability, BERGQUIST microTIM mTIM 1028 achieves durable thermal coupling through a thin elastomeric coating that resists abrasion, preserves surface flatness tolerances (<75 μm), and sustains optical module efficiency. Its unique formulation optimizes energy dissipation, mitigates hotspots, and supports long term bandwidth reliability demanded by future proof electro optical architectures.