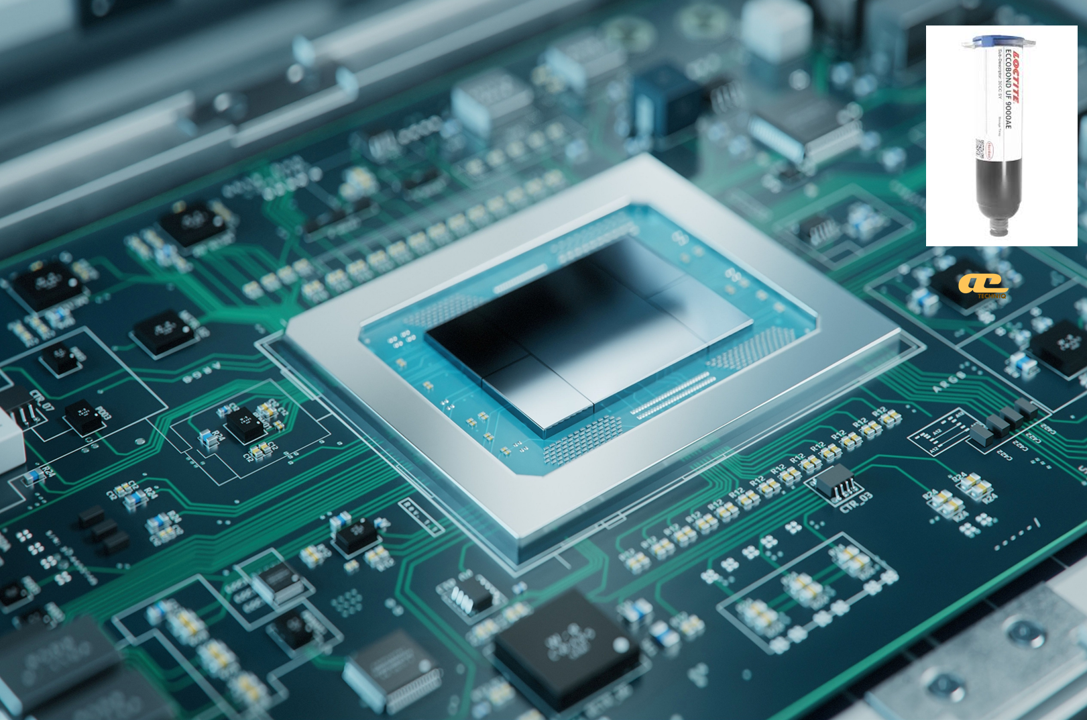

Enabling High-Performance AI and HPC Semiconductor Packaging with Advanced Underfill Technology

As artificial intelligence (AI) and high-performance computing (HPC) drive unprecedented demands on semiconductor devices, the need for reliable large-die protection and void-free encapsulation has never been greater. Henkel introduces Loctite Eccobond UF 9000AE, a capillary underfill engineered to meet the dimensional and electrical challenges of flip-chip BGA, high-density fan-out (HD-FO), and 2.5-D advanced packaging applications.

✨ Market Trends

Emerging AI and HPC devices utilize high-density, low-gap interconnects on large die (>40 mm × 40 mm) and substantial package bodies (>100 mm × 100 mm), creating critical requirements for bump protection, warpage control, and thermal management. Capillary underfills that combine low coefficient of thermal expansion (CTE), minimal shrinkage, and fast flow rates are becoming essential for maintaining high production yield and device reliability.

✨ Applications

Loctite Eccobond UF 9000AE is optimized for high-density flip-chip interconnects, Cu pillar bumps, and large-body semiconductor packages. It ensures comprehensive encapsulation of fine-pitch (~100 µm), low-gap (~50 µm) die interconnects, making it ideal for AI accelerators, HPC modules, and next-generation 2.5-D and wafer-level packaging designs.

✨ Highlights

- Fast, void-free capillary flow: 20% faster than prior-generation underfills, enabling edge-to-edge coverage.

- Thermo-mechanical resilience: Low CTE and high toughness reduce die and underfill cracking while controlling warpage.

- Electrical and moisture reliability: Ensures long-term functionality under thermal cycling and environmental stress.

- Process efficiency: Low resin bleed out and narrow fillet formation support dense die integration and high-throughput assembly.

✨ Product Advantages

Loctite Eccobond UF 9000AE combines materials science innovation with precision engineering to deliver reliable encapsulation, superior thermal and electrical performance, and enhanced manufacturing efficiency. By protecting fine-pitch interconnects against mechanical stress and environmental exposure, this underfill preserves device integrity, supports large-die scalability, and empowers semiconductor manufacturers to meet the evolving demands of AI and HPC markets.