How can advanced thermal management and protective materials ensure the long-term stability of high-voltage power conversion and energy storage systems?

✨ Market Trends: With solar capacity surpassing 350 GW and Li-ion storage scaling at record pace, alternative energy technologies face unprecedented performance requirements. The shift toward wide bandgap semiconductors such as GaN drives higher efficiency but also intensifies challenges in thermal dissipation, electrostatic stability, and environmental resistance.

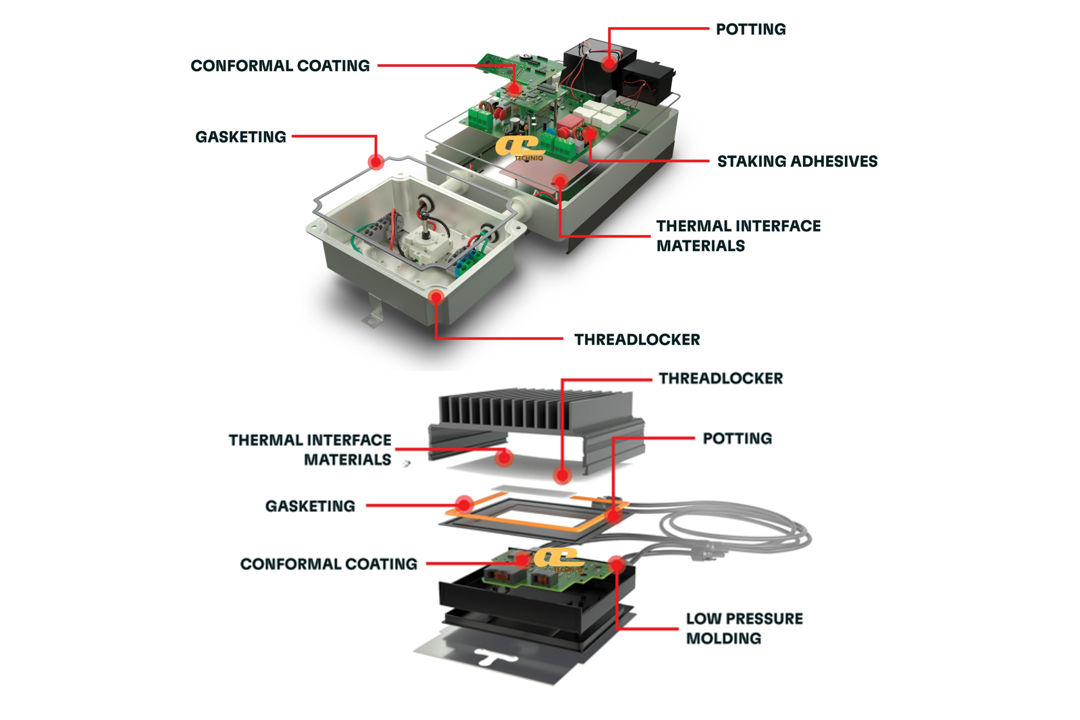

✨ Applications: Henkel’s formulations serve critical nodes of renewable infrastructure, from 1500 VDC central inverters to long-lifecycle Li-ion battery arrays. By integrating phase change TIMs, liquid gap fillers, conformal coatings, encapsulants, and gasketing solutions, Henkel delivers holistic reliability for residential, commercial, and utility-scale installations exposed to fluctuating temperatures, humidity, and outdoor contaminants.

✨ Highlights: The portfolio spans thermal interface materials that minimize thermal impedance, dielectric conformal coatings that prevent voltage leakage, potting encapsulants that secure electrochemical resilience, and sealing systems that guarantee ingress protection. Each material leverages field-specific expertise in electrostatics, polymer science, and surface engineering to achieve reliable performance across decades-long operation.

✨ Product Advantage: Henkel’s materials combine efficiency with sustainability: solvent-free chemistries reduce VOC emissions, UV and moisture-curable coatings optimize processing speed, and advanced TIMs extend component lifetimes while lowering thermal resistance. The result is not only longer service reliability, up to 25 to 30 years in many cases, but also reduced total cost of ownership, making alternative energy systems more scalable and economically viable.