Ensuring Peak Automotive Electronics Performance in an Evolving Era

As vehicles become increasingly connected and autonomous systems integrate into everyday driving, the reliability, durability, and precision of electronic components are paramount. Henkel’s latest Loctite automotive potting solutions are engineered to address these challenges, providing unparalleled protection against mechanical, thermal, and chemical stresses that threaten component integrity.

✨ Market Trends

With the automotive industry accelerating towards electrification and smart systems, electronic modules such as ECU connectors, sensors, and e-motors are subjected to higher thermal loads, fluid exposure, and mechanical vibration. This evolution demands advanced materials that combine electrical insulation, thermal management, and environmental protection in compact, process-friendly formats.

✨ Applications

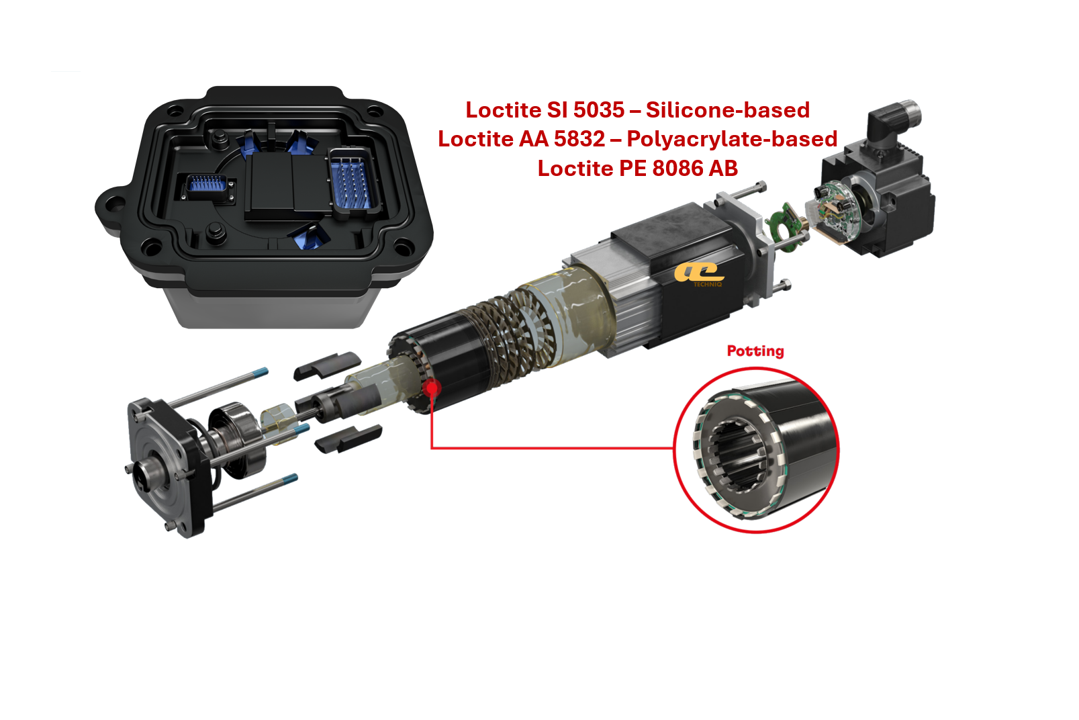

Henkel’s expanded portfolio includes three specialized potting adhesives designed for precise integration into automotive manufacturing lines:

- Loctite SI 5035 – Silicone-based, one-part sealant for moisture and corrosion protection.

- Loctite AA 5832 – Polyacrylate-based, dual-cure potting for sealing against transmission fluids and oils.

- Loctite PE 8086 AB – Two-component epoxy combining thermal conductivity and mechanical resilience for high-temperature environments

✨ Highlights

Deep UV/visible cure and secondary moisture cure mechanisms for shadow areas.

Rapid processing with minimal energy consumption and reduced factory footprint.

High thermal conductivity, low viscosity, and superior electrical insulation for electronics protection.

Enhanced resistance to fluids, thermal shocks, and mechanical stress.

✨ Product Advantages

These solutions enable efficient encapsulation and long-term reliability of automotive electronics. By minimizing curing time, reducing resource consumption, and optimizing compatibility with common substrates, Henkel’s potting materials ensure component longevity, peak performance, and sustainable production practices. From protecting sensitive ECUs to maintaining optimal