How does Loctite SI 5972FC redefine electronic module sealing in the era of electrification and autonomous mobility?

✨ Market Trends: The rapid adoption of electrification, e-mobility, and autonomous driving is driving unprecedented demand for high-reliability automotive electronics. Manufacturers face pressure to optimize electrochemical compatibility, minimize electrostatic risk, and shorten production cycles, while also meeting stringent OEM safety, sustainability, and REACH compliance standards.

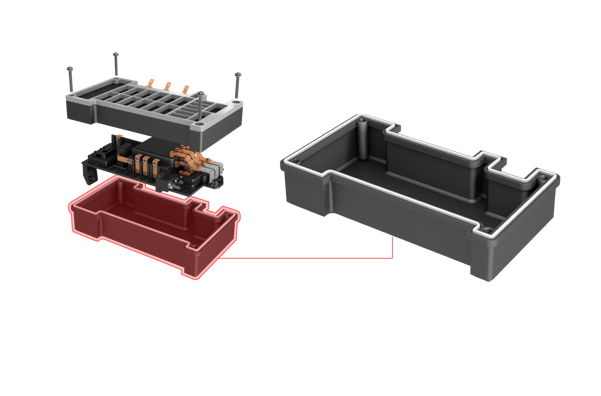

✨ Applications: Loctite SI 5972FC is engineered for sealing Electronic Control Units (ECU), Bussed Electric Centers (BEC), Battery Disconnect Units (BDU), Electrical Power Steering (EPS) power packs, and ADAS radar modules. Its advanced RTV chemistry allows immediate pressure resistance after dispensing, eliminating long staging times and enabling seamless in-line assembly.

✨ Highlights: With its one-part RTV silicone formulation, Loctite SI 5972FC provides instant sealing performance, successfully passing OEM leak and blow-out tests immediately after assembly. Its low-volatility, non-corrosive formulation (D4–D10 <0.1%) safeguards sensitive semiconductor and electrostatic components, while adhesion to multiple substrates ensures reliable performance under complex environmental stresses. The tin-free catalyst and alkoxy cure system further reinforce safety, compliance, and long-term electrochemical stability.

✨ Product Advantage: Loctite SI 5972FC accelerates production throughput by eliminating the need for post-assembly curing ovens, reducing both cycle times and energy consumption. This innovation not only enhances operational efficiency but also supports sustainable manufacturing by lowering CO₂ emissions and resource consumption, aligning with global goals for greener automotive technologies.