How does next-generation conformal coating technology secure electronics against extreme environmental stress while advancing safety and sustainability?

✨ Market Trends: The global transition toward electrification, renewable energy, and industrial automation is accelerating the demand for high-reliability protection of PCBs and power electronics. Market priorities now converge on three imperatives: safeguarding functionality under harsh environmental conditions, ensuring compliance with stringent safety standards, and aligning with sustainability objectives through solvent-free, energy-efficient materials.

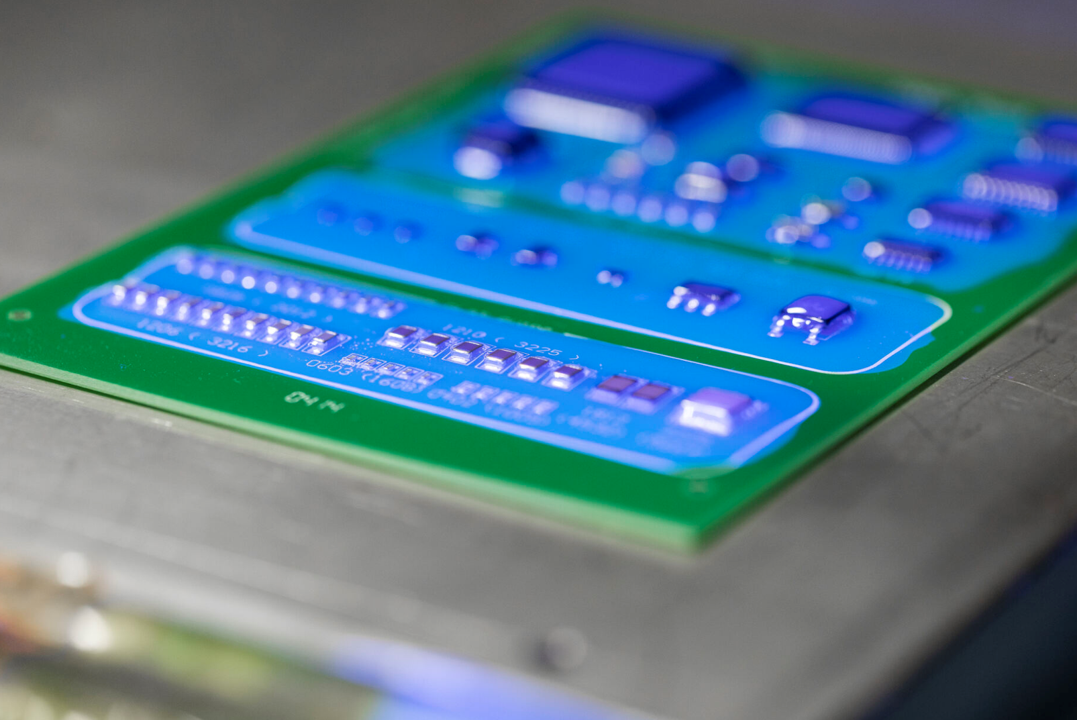

✨ Applications: Loctite Stycast CC 8555 is engineered for high-power electronics such as motor drives, programmable logic controllers (PLCs), EV charging stations, AC/DC power supplies, and renewable energy conversion systems. By providing superior dielectric insulation and resistance to moisture, corrosive gases, and aggressive chemicals, the coating ensures uninterrupted operation of mission-critical equipment deployed in industrial plants, outdoor environments, and next-generation mobility infrastructure.

✨ Highlights: The coating meets the most demanding benchmarks, including UL 746E RTI 130 °C, UL 94 V0 flammability rating, and IPC-CC-830 compliance. With a dielectric strength of 27.5 kV/mm and high surface insulation resistance, it guarantees stable electrostatic and electrical performance. Processability is equally strong: UV primary cure in seconds, moisture cure for shadowed zones, and excellent wetting and leveling deliver flawless PCB coverage. Its VOC- and solvent-free chemistry aligns with modern environmental regulations and operator safety.

✨ Product Advantage: Loctite Stycast CC 8555 provides a balance of performance, efficiency, and sustainability unmatched by solvent-based systems. It achieves protective coverage with only one-third to one-half the spray volume, lowering material usage and total cost of ownership. By eliminating heat-based curing, it reduces energy consumption and cycle times. The result is a conformal coating that not only protects sensitive electronics in the most severe operating conditions but also meets the global call for safer, cleaner, and more economical manufacturing practices.