How can encapsulation technologies redefine the reliability of next-generation IoT and Industrial Electronics?

✨ Market Trends: With the rapid expansion of IoT, IIoT, e-mobility, and digitalized healthcare, demand for lightweight yet resilient encapsulation materials is accelerating. Sustainability and miniaturization drive adoption of bio-based, RoHS-compliant thermoplastic resins that protect sensitive circuits under extreme thermal, chemical, and mechanical stresses.

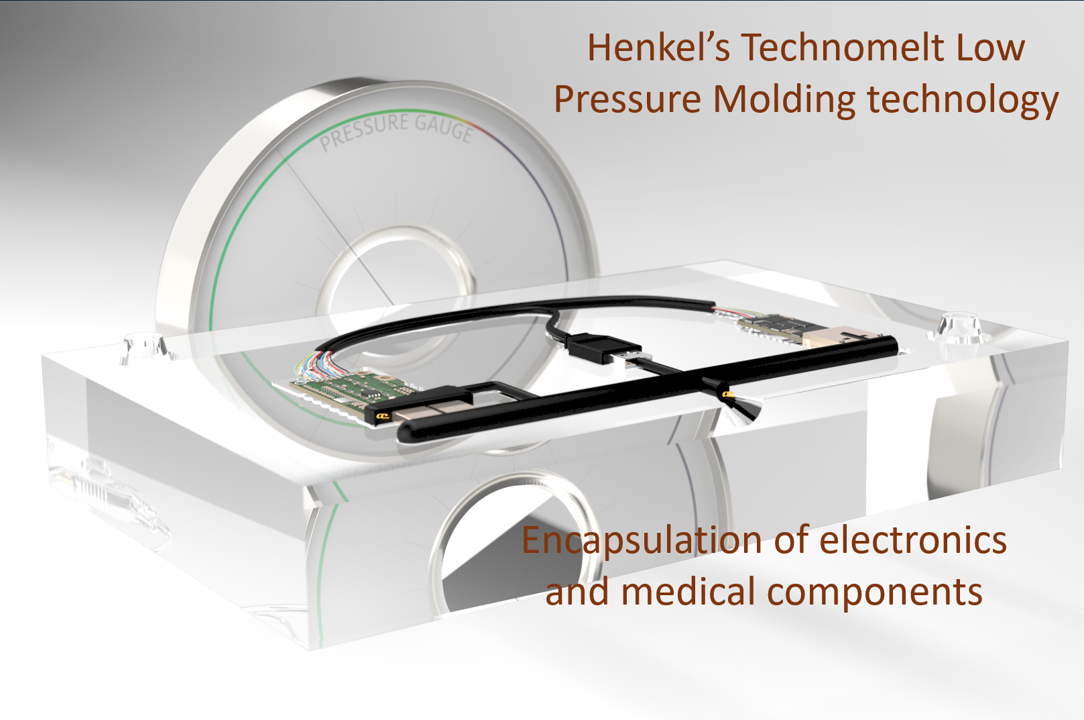

✨ Applications: TECHNOMELT® Low Pressure Molding polyamides deliver precision encapsulation of PCBs, PCBAs, connectors, sensors, power modules, LEDs, HVAC controllers, and wearable medical devices, while also enabling leakproof integration in liquid-delivery systems.

✨ Highlights: Unlike conventional epoxy potting or conformal coating, this single-component thermoplastic process ensures cycle times as short as 30 seconds, eliminates VOC emissions, and minimizes material consumption by molding to exact cavity geometries.

✨ Product Advantage: Superior electrical insulation, electrostatic discharge resistance, and barrier performance against dust, UV, and moisture combine with high vibration tolerance, low-cost aluminum or 3D-printed tooling, and up to 80% bio-based content—creating a high-performance, sustainable solution for complex electronics.