How can e-mobility components achieve reliable thermal management, mechanical resilience, and long-term operational safety?

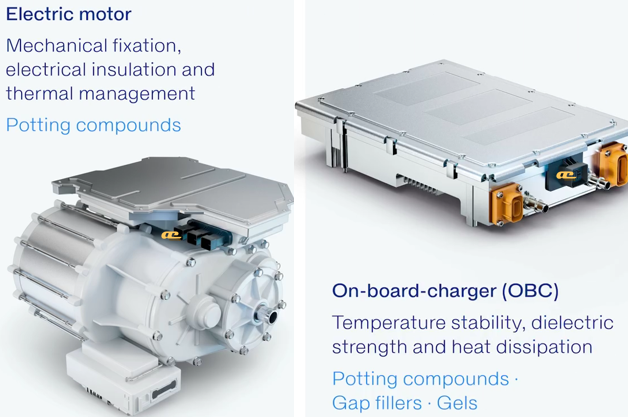

✨ Market Trends: The accelerating adoption of electric vehicles and energy storage systems demands materials that combine high thermal conductivity, chemical resistance, and mechanical stability. Components such as electric motors, battery modules, and on-board chargers require advanced potting compounds, adhesives, sealants, and gap fillers to ensure optimal performance and long service life.

✨ Applications: Wevo’s polyurethane, epoxy, and silicone-based 2K materials are designed for encapsulation and protection of battery cells, PCB-mounted electronics, electric motors, on-board chargers, and power electronics. They can be applied as CIPGs or FIPGs for fully automated assembly lines.

✨ Highlights: These customised materials provide excellent heat dissipation, low viscosity for void-free potting, high elongation and flexibility, and compliance with UL 94 flammability standards. They withstand chemical and thermal stress while preventing mechanical fatigue and partial discharges in high-density electronic components.

✨ Product Advantage: By combining precise property tuning, chemical resilience, and rapid processing, Wevo’s materials ensure enhanced operational reliability, longer maintenance intervals, and improved performance of modern e-mobility systems.